Home / MCM / History / 2010-2020

2010-2020

2010

The ‘Level2’ service package of jFMX supervisor is placed on the market, allowing production control to be extended from the single FMS / production cell level to the factory level. New opportunities open up for the integration of automation systems and solutions.

2011

MCM develops in co-engineering with Messier Bugatti Dowty (now Safran Landing Systems) a system consisting of four multitasking Tank 1600 equipped with a dividing unit and a special pallet exchanger dedicated to the machining of wheels and braking systems for aircrafts.

2012

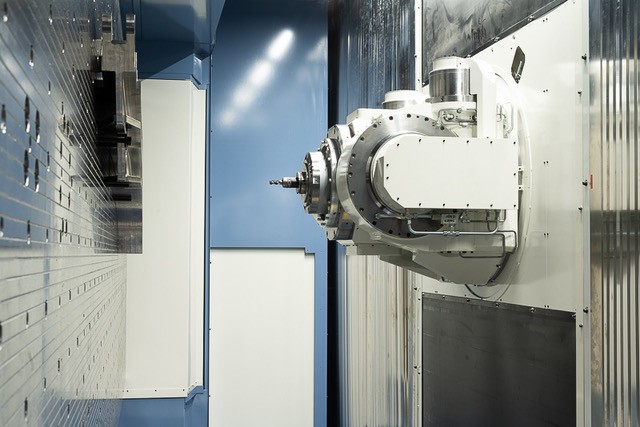

Debut of 5-axis and 6-axis Clock Dynamic machining centre, available in multitasking version, particularly suitable for the manufacture of small and medium sized components with complex geometry, such as blades for oil & gas turbines.

2013

Safran Aircraft Engines entrusts MCM with the construction of the FMS system consisting of 12 multi-tasking Tanks equipped with dividing unit and special pallet exchanger to ensure the machining of titanium disks for LEAP engine.

2014

RIFA Group acquires control of MCM S.p.A.

2015

MCM and Nuovo Pignone GE Oil &Gas implement an ambitious project of technological integration and synergistic automation. This plant integrates MCM machines, unconventional technologies, storage and measuring systems and robots.

2016

AIRBUS places an important order for the construction of 6 Jet-Five machines in FMS configuration for machining of structural components in hard-to-machine materials (titanium alloys, special steels).

2017

The jFMX structure is changed to include ‘Level0 - Flight Recorders’, which allows the most advanced collection and monitoring of data from machine sensors, supports preventive maintenance, extends life cycle management and defines the maintainability of machining centers and FMSs.

2018

A new version of Clock family machining centers (800 and 1200) is developed.

MCM strengthens its presence on the Chinese market by winning an important order for AVIC (Aviation Industry Corporation of China) consisting of 10 Tanks 1900 in FMS configuration (mainly for the machining of aluminium alloys) and 3 Jet-Fives (version for titanium).

.jpg)

.jpg)